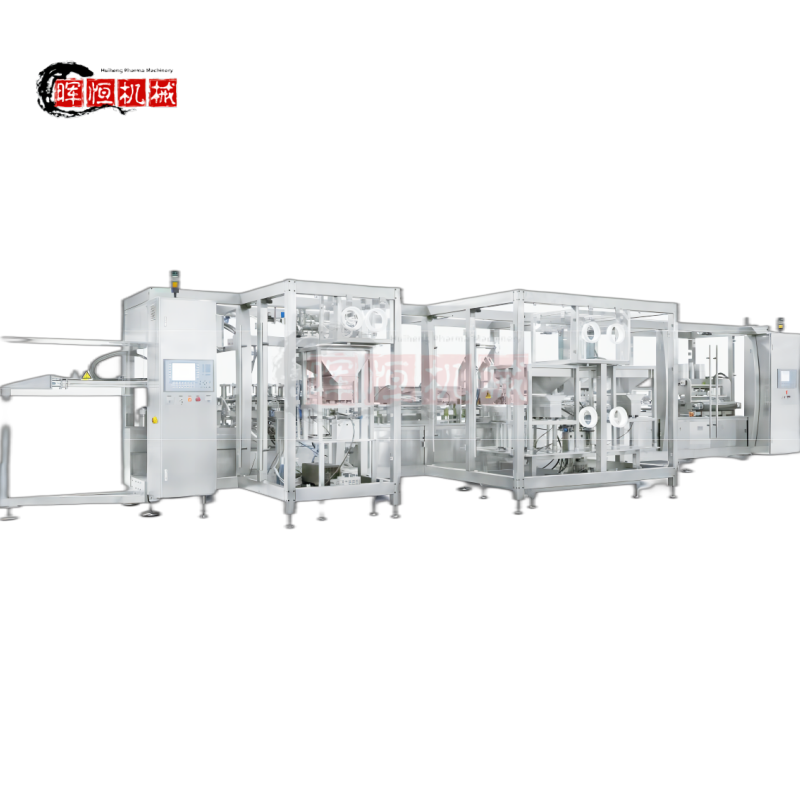

Name:Non-PVC Soft Bag Form-Fill-Seal Machine

Brand: HUIHENG PHARMA

Material:SUS316L/SUS304

Warranty 12 Months

Fully Automatic Introvenous Solution Production Plant IV Fluids Filling Washing Sealing Packing Machine IV Infusion Bag Line

Non-PVC Soft Bag IV Solution Production Line

Product Description

HUIHENG PHARMA proudly presents its cutting-edge Non-PVC soft bag IV solution production line, incorporating the latest advancements in technology. This sophisticated system seamlessly executes film feeding, printing, bag manufacturing, filling, and sealing within a single, integrated machine.

Engineered for adaptability, our production line accommodates 50-5000ml Non-PVC soft bags, catering to a diverse array of solutions, including general, special, dialysis, parenteral nutrition, antibiotics, irrigation, and disinfectant solutions. The machinery offers an extensive range of PP bag designs, featuring options such as single boat-type ports, single/double hard ports, double soft tube ports, and more.

Experience unparalleled precision and flexibility in IV solution manufacturing through HUIHENG PHARMA's state-of-the-art production solutions.

This holistic approach to automation enhances productivity and minimizes the risk of human error, resulting in Non-PVC soft bags of the highest quality. The synchronized coordination of film feeding, printing, bag making, filling, and sealing exemplifies the cutting-edge capabilities of HUIHENG PHARMA's production line, positioning it at the forefront of modern manufacturing in the healthcare industry.

Production Process

The Non-PVC soft bag production line by HUIHENG PHARMA epitomizes a seamless and efficient manufacturing process, automating critical stages to ensure precision and top-notch quality. The process initiates with automated film feeding, where HUIHENG PHARMA's selected materials are precisely dispensed for subsequent stages. Subsequently, the system seamlessly integrates printing, allowing for customizable and branded solutions.

The bag-making stage showcases advanced technology, with HUIHENG PHARMA's machinery intricately forming the bags with precision. Following this, the automated filling process, in adherence to strict quality standards, ensures accurate and consistent product volumes. The final touch involves HUIHENG PHARMA's sealing mechanism, guaranteeing a secure and airtight closure.

It can automatically feed film to the printing and forming station, the film roll is fixed by easy operated cylinder clamps. The fixation doesn’t need any tools and manual labor.

This station adopts mechanical film-open plate. The opening of film is 100% guaranteed. Any other film opening method doesn’t have a guarantee of 100%, but also the system is far more complicated.

Peripheral welding with bilaterally open moulds structure, up and down moulds are opened bilaterally and equipped with cooling plate, to heat both moulds to the same temperature up to 140℃ and above. No film over-baked during bag forming or machine stopping. Improve the product welding quality and save more film.

Because of the different material and thickness between the boat type ports and the film, it adopts 2 pre-heating, 2 heat seal welding and 1 cool welding,to enable it to suit with different plastic material and film, bring the user more selection, higher welding quality, low leakage rate within 0.3‰.

Adopt the E + H mass flowmeter measurement and high-pressure filling system. High filling accuracy, no bag and no qualified bag, no filling.

Each welding end shield use separate cylinder driving, and drive unit is hidden in the base, guide use linear bearing, without any mark and particles, ensure product transparent degree.

The finished products will be outputted through conveying belt to the next procedure.

Product Features

● 100% film utilization: No waste edge between bags, reducing both material and energy consumption.

● Reliable heating and welding system: Leakage rate less than 0.03%.

● Quick changeover: 0.5-1 hour to switch from one size to another.

● Compact structure, reduce 1/3 length of the machine, save room space and running cost.

● Stable running and transmission system: only need 1 control system, 1 HMI and 1 operator.

● Safe filling nozzle: No solution overflows, no particles generation.

● Auto detection and faulty rejection system.

Technical Specifications:

Item | Main Content | ||||||||

Model | SHH-SRD1A | SHH-SRD2A | SRS2A | SHH-SRD3A | SHH-SRD4A | SRS4A | SHH-SRD6A | SHH-SRD12A | |

Actual Production Capacity | 100ML | 1000 | 2200 | 2200 | 3200 | 4000 | 4000 | 5500 | 10000 |

250ML | 1000 | 2200 | 2200 | 3200 | 4000 | 4000 | 5500 | 10000 | |

500ML | 900 | 2000 | 2000 | 2800 | 3600 | 3600 | 5000 | 8000 | |

1000ML | 800 | 1600 | 1600 | 2200 | 3000 | 3000 | 4500 | 7500 | |

Power Source | 3 Phase 380V 50Hz | ||||||||

Power | 8KW | 22KW | 22KW | 26KW | 32KW | 28KW | 32KW | 60KW | |

Compressed Air Pressure | Dry and oil-free compressed air, the cleaness is 5um,the pressure is over 0.6Mpa.The machine will automatically warn and stop when the pressure is too low | ||||||||

Compressed Air Consumption | 1000L/mim | 2000L/mim | 2200L/mim | 2500L/mim | 3000L/mim | 3800L/mim | 4000L/mim | 7000L/mim | |

Clean Air Pressure | The pressure of clean compressed air is over 0.4Mpa, the cleaness is 0.22um | ||||||||

Clean Air Consumption | 500L/min | 800L/min | 600L/min | 900L/min | 1000L/min | 1000L/min | 1200L/min | 2000L/min | |

Cooling Water Pressure | >0.5kgf/cm2 (50kpa) | ||||||||

Cooling Water Consumption | 100L/H | ||||||||

Details:

Contact: Kevin

Phone: 008613166139318

E-mail: Kevinpharmachinery@gmail.com

Whatsapp:008613166139318

Add: Rm 808, No. 6088, Humin Road, Xinzhuang Town, Minhang District, Shanghai, China P.C.: 201100

We chat