Brand:HUIHENG Pharma

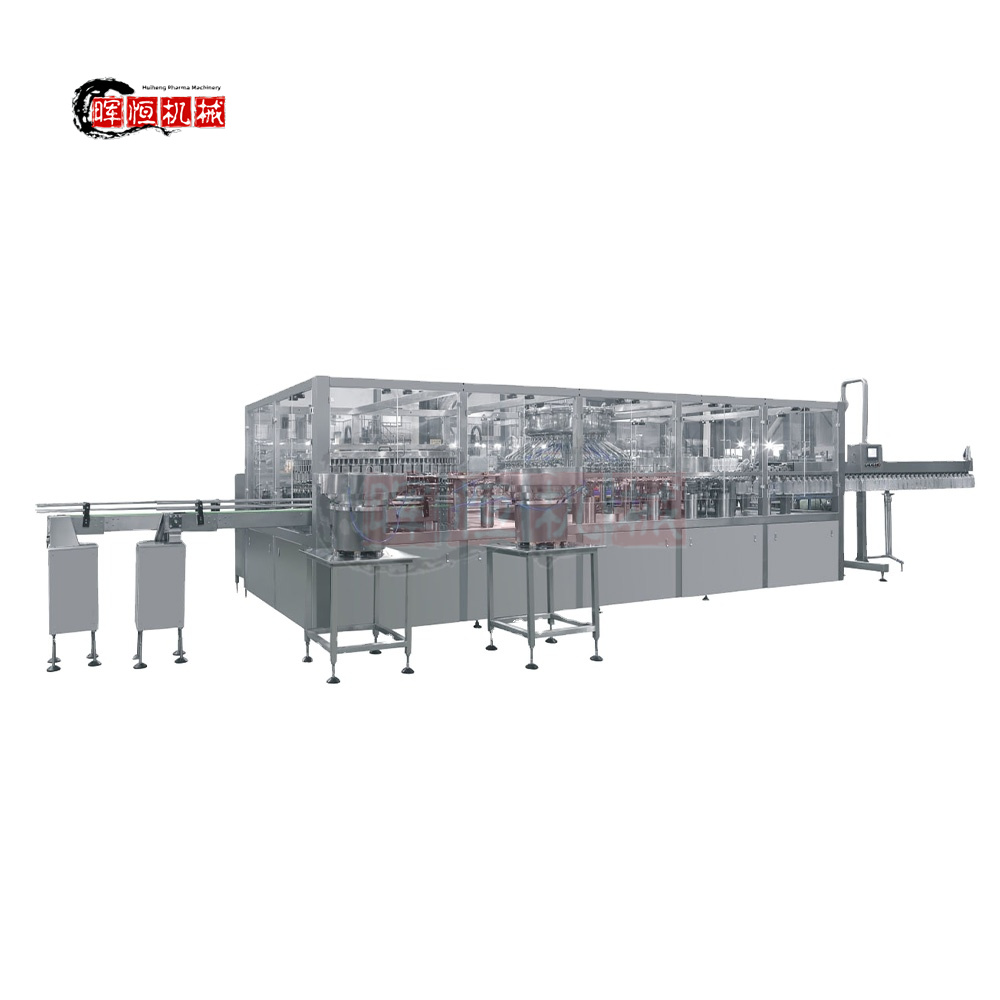

Processing Types:Automatic Blowing Washing Filling Capping Machine

Product Name:PP Bottle IV Infusion Poduction Line

Material:SS304/SS316L

Best Quality Infusion Filling Sealing Capping Drying PP Bottle IV Solution Production Line

Product Description

The machine is mainly used for the washing, filling and sealing of PP bottle infusion. It is suitable for hot sealing of combined cap, it includes ion wind washing unit, WFI washing unit, time-pressure filling unit, sealing unit/ capping unit.

Overview

The machine is mainly used for the washing, filling and sealing of PP bottle infusion. It is suitable for hot sealing of combined cap,

it includes ion wind washing unit, WFI washing unit, time-pressure filling unit, sealing unit/ capping unit.

Production capacity (@250ml): 8,000; 10,000; 12,000 bottles/hour;

Equipment Features:

Compact structure and minimum operators. Except the operators monitoring bottle feeding, only one operator is required.

Online iron generation monitor is provided. If static electricity quantity of washed bottle exceeds the set-point, there is no filling and capping and alarm will generate.

Machine shuts down when one door is opened.

Functions are provided, such as automatic cap unscrambling, cap feeding and no bottle no capping.

The heating plate of the sealing device is provided with an anti-collision device.

GMP compliant CIP&SIP function are provided.

Bottle feeding chain connected to bottle blowing machine can be selected.

Adjustable exhaust device for control deformation of bottles after sterilization

Plastic bottle washing, filling and sealing production line

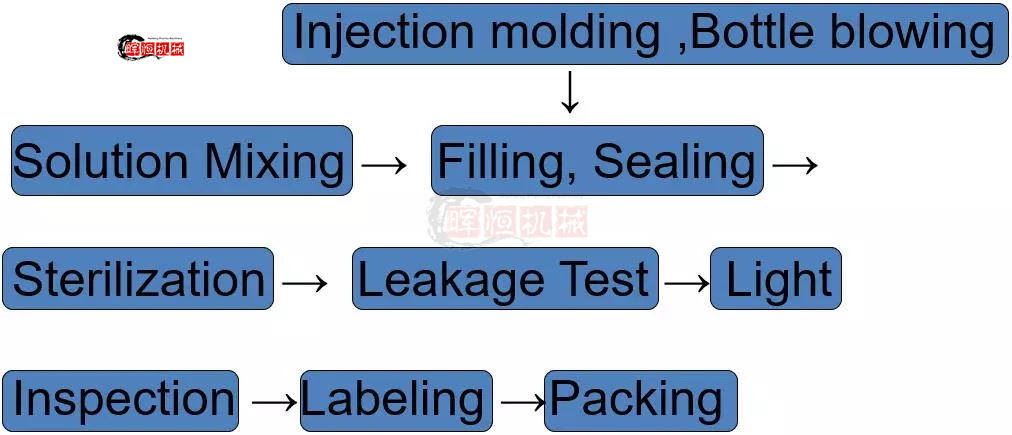

Production Process

The machine is an all-in-one automated manufacturing system for high-volume sterile intravenous (IV) solution bottle production. It seamlessly integrates latest innovations in bottle forming, washing, filling and sealing for pharmaceutical grade quality and efficiency.

Blow Molding Machine

The blow molding machine is used to blow the PP bottles. It is a two-step blow molding machine, which can produce bottles with high precision and good appearance. The machine can be customized to produce bottles of different sizes and shapes.

Washing Machine

The washing machine is used to clean the bottles before filling. It uses high-pressure water to remove dirt and debris from the bottles. The machine also uses ultraviolet light to sterilize the bottles, ensuring the safety of the product.

Filling Machine

The filling machine is used to fill the bottles with liquid. It can be equipped with different types of filling heads to meet the needs of different liquids. The machine has a precise filling control system, which ensures that the bottles are filled with the correct amount of liquid.

Sealing Machine

The sealing machine is used to seal the bottles after filling. It uses a high-frequency sealing head to heat and seal the bottle cap, ensuring the airtightness of the bottle.

Technical Specifications

Project | Unit | QTY | |||

SHH(Q)30/24/24 | SHH30/30/24/24 | SHH(Q)48/40/56 | SHH42/48/40/56 | ||

Capacity | bottles/min | 50-120 | 50-120 | 150-300 | 150-300 |

Bottle shape and specifications | ml | 100/250/500 | |||

Washing station | pcs | 30 | 30 | 48 | 42 |

Water washing station | pcs | 30 | 48 | ||

Filling station | pcs | 24 | 24 | 40 | 40 |

Capping station | pcs | 24 | 24 | 56 | 56 |

Main motor | KW | 3.7 | 3.7 | 5.5 | 5.5 |

Cap collecting oscillator | KW | 0.5 | 0.5 | 0.5X2 | 0.5X2 |

Ionic Wind | KW | 0.01X30 | 0.01X30 | 0.01X48 | 0.01X42 |

Belt power | KW | 0.75 | |||

Heat board | KW | 25 | 25 | 20X3 | 20X3 |

Pure Air consumption (0.5-0.7MPa) | M3/min | 3-6 | |||

WFI consumption | M3/min | 0.3-0.8 | 0.9-1.8 | ||

Details:

Contact: Kevin

Phone: 008613166139318

E-mail: Kevinpharmachinery@gmail.com

Whatsapp:008613166139318

Add: Rm 808, No. 6088, Humin Road, Xinzhuang Town, Minhang District, Shanghai, China P.C.: 201100

We chat