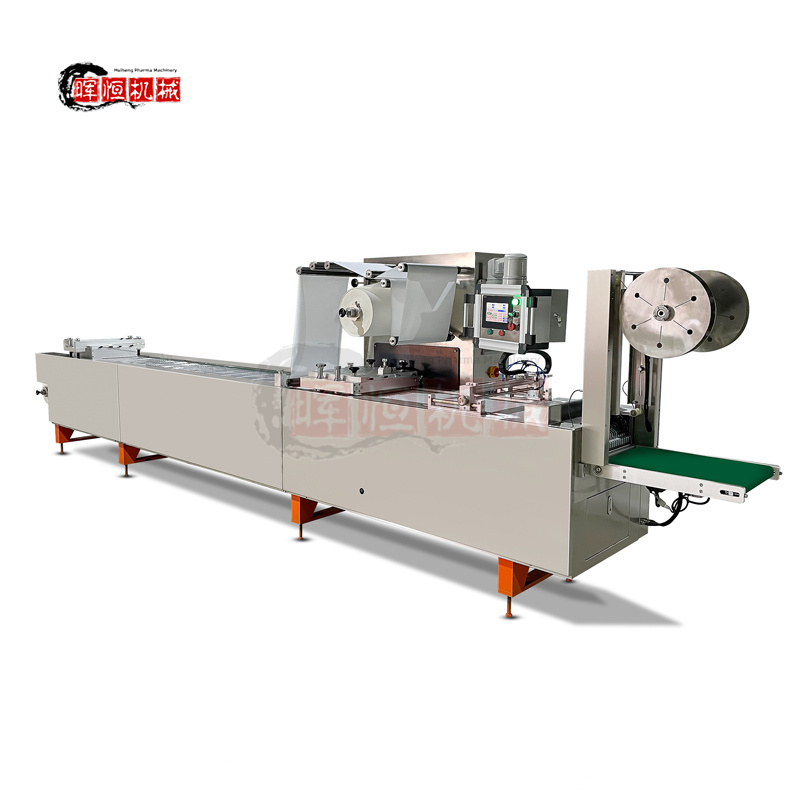

Name: SHH-DPB420 Disposable Medical Product Packing Machine/Syringe Blister Packing Machine

Model: SHH-DPB420

Applications: needle, tube, Syringe and others blister packing

SHH-DPB420 Disposable Medical Product Packing Machine/Syringe Blister Packing Machine

Product introduction:

SHH-DPB420 Disposable Medical Product Packing Machine/Syringe Blister Packing Machine is successful to develop the latest soft plastic packing machine in china by our factory and widely used the packing of medical apparatus(syringe needle, injector), chinese and western medicine, electron component, chemical product, food as well as sensitive anti-pollution materials.

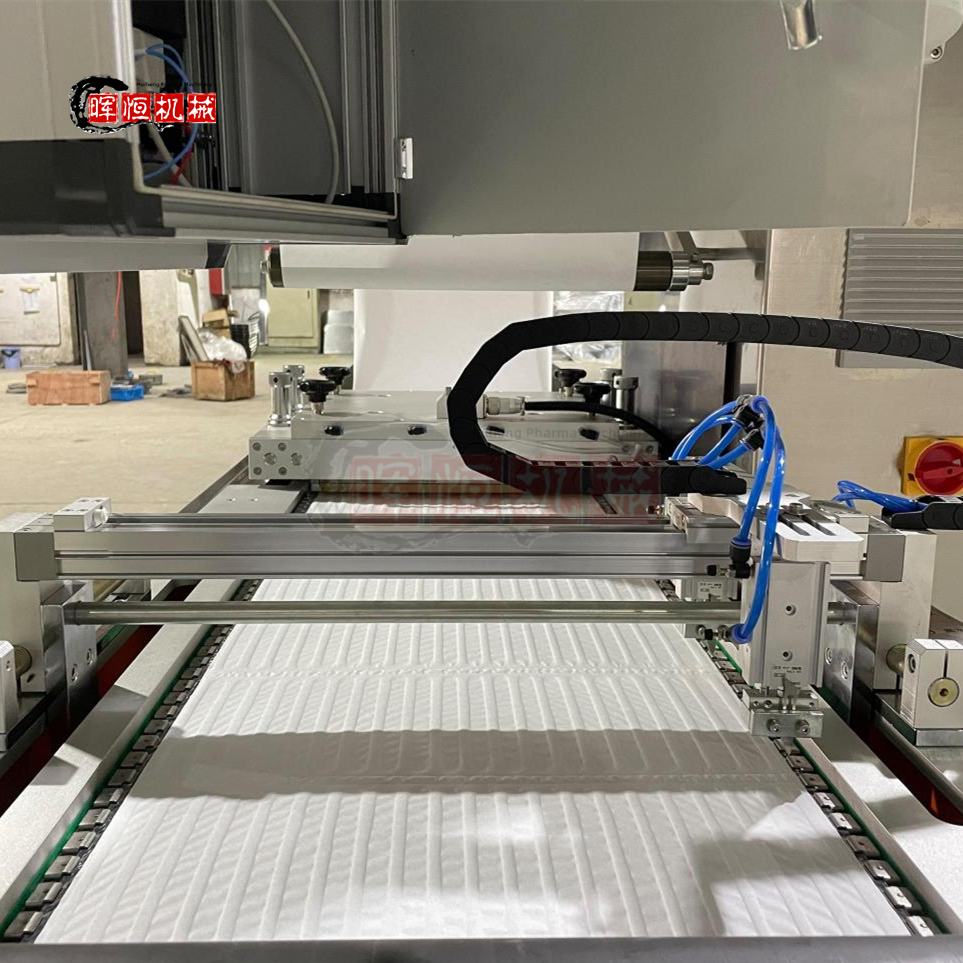

It can synchronously finish the full processing of heating in metching for PVC strip, negative pressure and positive pressure to form simultaneously, filling, plate net-pattern sealing, batch number printed, vertical and cross cutting and transfer the final product. It is a high automatic machine.

Feature of machine:

1. The machine body is a casting, which absorbs vibration and does not deform. The fuselage wall panels on both sides are made of No. 45 steel (thickness 16mm), which is rigid, heavy and stable;

2. The film chain is backward type, and the opening and closing action can be controlled in place, which conforms to European and American standards;

3. For standard size products such as syringes, the upper mold of the forming and heat sealing molds is replaced by a drawer type extraction, which does not need to disassemble the mold frame, and the mold frame does not need to be replaced for different strokes;

4. The positioning design of the lower mold pins of the forming and heat sealing molds, the replacement and positioning are simple and fast, and the disadvantages caused by screw fixing are avoided;

5. The mold and cutter stations all have external handwheels, which can easily adjust the position, suitable for molds with different strokes;

6. The heating method adopts the aluminum heating plate with uniform distribution and overall casting, which has uniform heating and long service life, avoiding the drawbacks of heating pipes;

7. The cross-cut can be flexibly adopted serrated cutting or scalpel type, which is convenient for maintenance and adjustment;

8. The cursor registration system adopts American Banner, which is accurate and reliable;

9. The temperature control adopts Mitsubishi temperature module, which has high precision and can easily realize data export and connection with MES system;

10. The automatic feeding system of the syringe adopts a chain-plate synchronous belt, which avoids the disadvantage of the screw scratching the printed content.

Technical Parameters:

Model | SHH-DPB420 |

Package Scope | Suitable for package of many sensitive anti-pollution materials |

Capability | (1) 20 syringe needles/time (2)1ml 11 injectors/time, |

Packing Frequency | 6-16 times / min |

Package Materials | Paper-plastic, Aluminum-plastic, Plastic-plastic and other Compound Film suitable for heat sealing(or the hard plastic less than |

Maximum inner dimension(mm) | 375*154* 50mm (L*W*D) |

Out Dimensions | 5000*980* 1860mm (L*W*H) |

Power(kw) | 10kw |

Weight(kg) | 1900kg |

Details:

Contact: Kevin

Phone: 008613166139318

E-mail: Kevinpharmachinery@gmail.com

Whatsapp:008613166139318

Add: Rm 808, No. 6088, Humin Road, Xinzhuang Town, Minhang District, Shanghai, China P.C.: 201100

We chat