Name: Automatic Aseptic Ampoule Washing Sterilizing Drying Filling Sealing production line for liquid

Model: SHH-AFS6-16

Brand: HUIHENG PHARMA

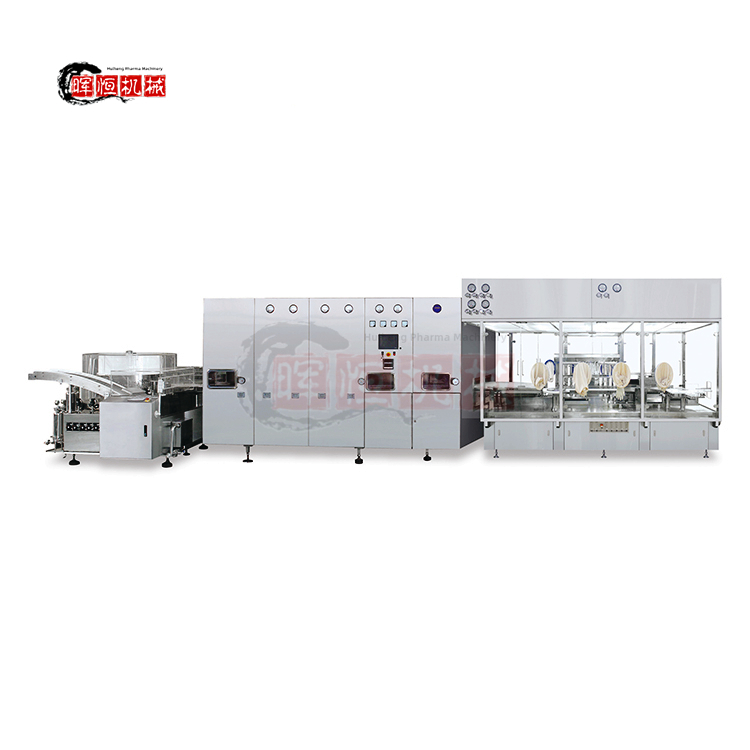

Automatic Aseptic Ampoule Washing Sterilizing Drying Filling Sealing production line for liquid

Brief Description:

This production line is composed of SHH-QCL series Vertical Ultrasonic Bottle Washing Machine, SHH-AMRS series Circulating Hot Air Tunnel Sterilization Oven and SHH-AFS series Vertical Fill-Seal Machine. It is used for the production of 1-20ml ampoule injection and includes three working area including washing area, drying and sterilization area, filling and sealing area, which can be used separately. The whole production line is mainly used for the small volume injection production and is composed of more than 20 procedures, such as water spraying, ultrasonic washing, manipulator taking bottles, bottle turnover, swashing (inner and outer surface of bottles), blowing (inner and outer surface of bottles), preheating, drying and sterilizing, cooling, (nitrogen filling), filling, (nitrogen filling), preheating and sealing.

Main Performance Characteristics:

* Ampoule Wash-Dry-Fill-Seal Production Line is used the washing, sterilization, filling and sealing of small volume ampoule injection in workshop. It features advanced design, reasonable structure, high degree of automation, stable and reliable operation, high production efficiency and mechanical and electrical integration. The parts contacted with drug liquid are made of AISI316L and the other are made of AISI304. The materials used have no pollution on drug and environment. The overall design and manufacturing are in line with FDA and the new GMP.

* Ampoule Wash-Dry-Fill-Seal Production Line is composed of Vertical Ultrasonic Washing Machine, Drying and Sterilization Oven, and Ampoule Fill-Seal Machine. It features coordination interaction, stepless speed regulation and accurate control and can meet production process requirements.

* It features high production spped, high qualification rate, no impact, no wrong action, no squeezing and on broken bottles.

* It is equipped with various safety devices to ensure the safety of the operator and machine.

* Validation ports are reserved on main parts.

* It features PLC control, touch screen operation and programmed production.

* Buffer devices are installed on the connection point between three units of the production line, thus able to ensure reliable and stable operation.

* It has the function of no bottle no filling.

* It has centralized oil supply system which can easily add oil on lubrication points.

Technical Parameter:

Specification | |||||

| Model | SHH-AFS6 | SHH-AFS8 | SHH-AFS10 | SHH-AFS12 | SHH-AFS16 |

Filling Head | 6 Head | 8 Head | 10 Head | 12 Head | 16 Head |

Suitable Size | 1-20ml(ampoule) | 1-10ml(ampoule) | |||

Production Capacity(pcs/h) | 6000-16000 | 8000-21000 | 10000-24000 | 12000-30000 | 16000-36000 |

Power Supply | 380V-50HZ | ||||

Power Capacity(KW) | 78 | 78 | 80 | 90 | 90 |

Total Weight | 8900 | 8900 | 9400 | 9700 | 10100 |

Overall Size(mm) | 9100*2200*2450 | 9100*2200*2450 | 9260*2200*2450 | 9910*2200*2450 | 10042*2200*2450 |

Details:

Contact: Kevin

Phone: 008613166139318

E-mail: Kevinpharmachinery@gmail.com

Whatsapp:008613166139318

Add: Rm 808, No. 6088, Humin Road, Xinzhuang Town, Minhang District, Shanghai, China P.C.: 201100

We chat